In the air conditioning and refrigeration system, the efficiency of the heat exchanger directly determines the EER of the whole unit, operation stability, and long-term reliability. As the core part of the heat exchanger for the air side, evaporator and condenser fins are normally infected by so many factors, such as stream condensation, dust accumulation, and corrosion, that as a result, their heat-exchange efficiency apparently decreases as time goes on. In recent years, as a new surface-strengthening technology, nano-coating is widely used on the surface of heat exchangers to improve the condensation characteristics, heat-exchange efficiency, and durability.

Now we are going to explain it systematically from the condensation mechanism, nano-coating operation function, coating types, heat-exchange performance improvement, and the application challenges.

I. Basic mechanism of condensation on the heat exchanger surface

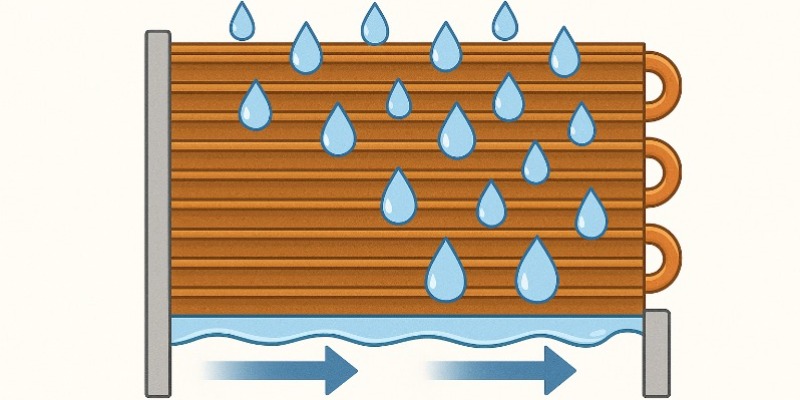

When the steam in the air attaches to the condenser fins with a temperature below the dew point, the water parcels will condense on the surface and form a water film or drops. The condensation forms are mainly two types:

1. Filmwise condensation

The steam continuously forms films on the surface, which lead to high heat resistance and low heat exchange efficiency.

2. Dropwise condensation

The steam forms drops and slides down quickly, which leads to low heat resistance and high heat exchange efficiency.

Aim: keeping the heat exchanger with a long-lasting dropwise condensation.

But traditional aluminum fins are vulnerable to oxygenation and form a hydrophilic surface. As time goes on, it will convert to filmwise condensation and lead to lower heat exchange efficiency.

II. How does the nano-coating improve condensation characteristics?

Nano-coating is a kind of functional surface technology. By changing the microstructure and surface energy through chemical or physical methods, it achieves the following effects:

Adjusting Surface Wettability (Hydrophilic/Hydrophobic)

Hydrophobic Nanocoating: it promotes the generation of water drops and sliding down quickly, which is conducive to dropwise condensation.

Hydrophilic Nanocoating: it allows water to spread quickly and form films, which reduces micro resistance and improves airflow accessibility.

III. Common nano-coatings and technical mechanisms

1. Fluoride/Silane Hydrophobic Nanocoatings

It forms a low surface energy layer to enhance the hydrophobicity.

Contact angle >120°.

Is it conducive to dropwise condensation and fast drainage?

2. Oxide Hydrophilic Nanocoatings (TiO₂, SiO₂)

Enhance surface hydrophilicity.

It allows water to spread quickly and form films in order to reduce water droplet blockage of airflow.

TiO₂ exhibits photocatalytic activity under light, providing mild self-cleaning.

3. Composite Nanocoatings (Ceramic + Polymer)

It features corrosion resistance, salt spray resistance, fouling resistance, enhanced thermal conductivity, and so on.

It is commonly used in condensers for highly corrosive coastal environments.

4. Metallic Nanocoatings

It uses silver or copper nanomaterials to improve thermal conductivity.

It is seldomly used due to the cost but primarily found in high-end heat exchange equipment.

IV. Performance improvement brought by the nano-coating

1. Improved heat exchange efficiency (5% - 25%)

Nano-coating allows the surface to fit dropwise condensation, apparently reducing the thermal resistance.

2. Reduced Condensation Retention (20–60%)

The coating reduces water bridges between fins, increasing airflow and reducing noise.

3. Improved Defrosting Capacity (Heat Pump Applications)

The hydrophobic coating reduces ice buildup, which results in complete defrosting with less frequency.

4. Corrosion Protection and Extended Lifespan

Some nano-coatings can increase salt spray test lifespan by 300 - 1000 hours.

5. Reduced Energy Consumption

After the increasing of heat exchange efficiency, the system operation pressure will be decreased, and it will save 3% - 10% energy.

V. Challenges and notifications of application

1. Coating may affect thermal conductivity

Thick or thin or uneven coating may increase the resistance of heat conductivity, so the thickness of coating must be controlled at the nanometer level.

2. Coating adhesion determines lifespan.

Humid heat, thermal cycling, and high-wind-speed environments can all cause coating peeling; therefore, process selection is crucial.

3. Cost considerations.

Additional coating means additional cost; high-performance coating means high additional cost. Nano-coating is more suitable for mid-to-end models or special environments.

4. Differences in environmental suitability.

To select a hydrophobic or hydrophilic coating, it depends on the operating conditions and should not be used blindly.

Nano-coating provides a high-efficiency, reliable, and quantifiable solution for the improvement of condensation characteristics on the heat exchanger surface. With the development of the material technology, nano-coating will steadily become the key means for the performance improvement and differentiated competition in the air conditioning industry.